Horizontal Boring-Milling Machine - This is a type of machining equipment primarily used for milling and boring operations. Its worktable is horizontally mounted, hence the name "horizontal." The design of the horizontal boring-milling machine ensures that the workpiece can be securely fixed during machining, making it suitable for processing large-sized or heavy workpieces.

Main Features and Applications:

- Milling Function: The milling machine uses a rotating milling cutter to cut the workpiece, suitable for processing flat surfaces, grooves, gears, and other shapes.

- Boring Function: Boring involves fixing the workpiece on the worktable and using a boring tool for high-precision machining, commonly used for creating precise holes or resizing existing ones.

- Scope of Application: Horizontal boring-milling machines are typically used for mass production or processing large-sized workpieces, such as molds, automotive components, and aerospace equipment.

- Flexibility and Precision: The equipment allows feed in different directions and can be equipped with various types of milling and boring tools to meet diverse machining needs.

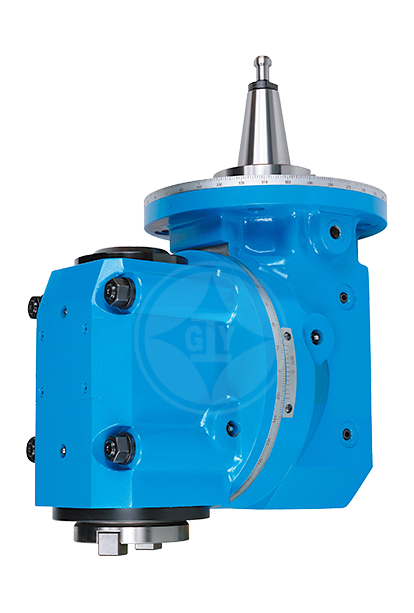

- Attachment of Auxiliary Heads: Enables the horizontal machine to switch to vertical machining, transforming the horizontal platform into a multifunctional machine, saving time and effort while making machining faster and more convenient.

In summary, the horizontal boring-milling machine is a versatile, heavy-duty machining tool widely used in industries requiring high precision and complex machining processes.