Gantry Milling Machine - is a type of large milling machinery typically used for heavy-duty machining operations. The term "gantry" refers to the machine's frame structure, resembling a gate or arch shape in appearance, which gives it its name. This design enables the machine to support and process larger or heavier workpieces.

Main Features of a Gantry Milling Machine:

Main Features of a Gantry Milling Machine:

- Large Working Area: Gantry milling machines are equipped with spacious worktables and high vertical machining capacity, making them suitable for processing large or heavy workpieces.

- Rigid Structure: The robust design of the machine helps absorb high-intensity forces and vibrations generated during the milling process, ensuring machining precision.

- Multi-functional Machining Operations: Gantry milling machines can perform various milling operations, such as face milling, slot milling, contour milling, and more, suitable for processing large parts made of materials like metal.

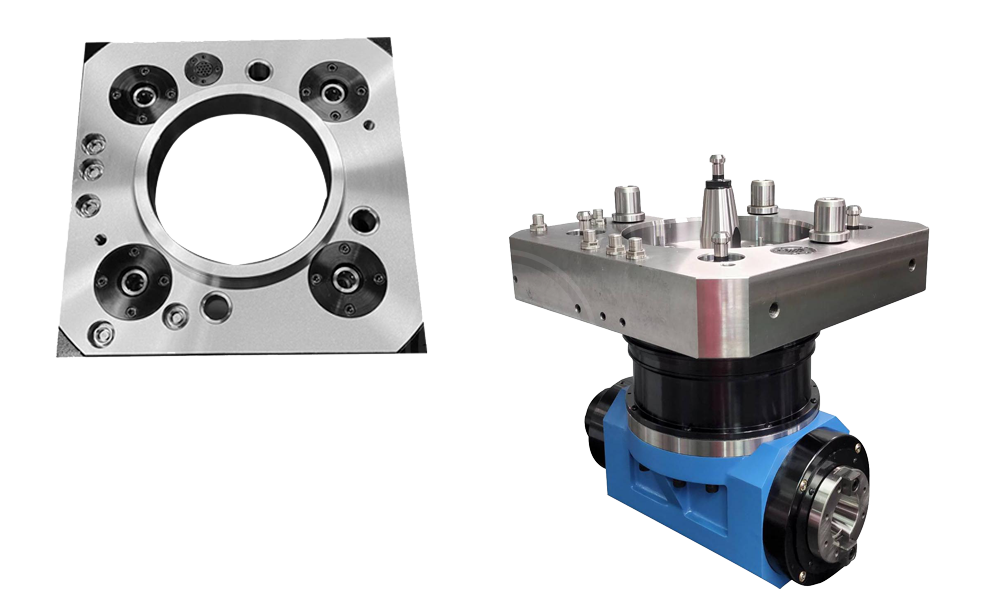

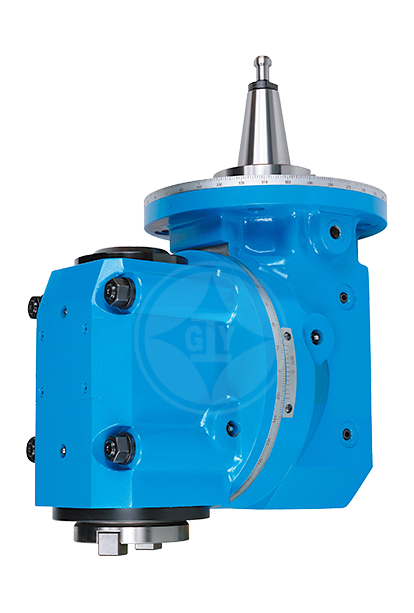

- Additional Auxiliary Attachment Heads: Since gantry machines often handle large workpieces, flipping them for further processing is challenging and time-consuming. Additionally, the work surface may shift, affecting precision. Installing auxiliary attachment heads can overcome these issues.

Gantry milling machines are widely used in industries such as aerospace, automotive, shipbuilding, and heavy equipment manufacturing, particularly in applications requiring high-precision machining of large components.